In an era where the global food supply chain faces unprecedented demands, the integration of Internet of Things (IoT)-based cold chain solutions is transforming the agri-logistics sector with remarkable speed and impact, reshaping how perishable goods are handled worldwide. Valued at US$ 18.5 billion in 2024, this market is projected to soar to an astonishing US$ 149.9 billion by 2034, driven by a compound annual growth rate (CAGR) of 23.9%. This staggering growth underscores how IoT technologies are redefining the handling of temperature-sensitive agricultural products, ensuring that items like dairy, fruits, vegetables, meat, and seafood maintain their quality from farm to consumer. More than just a technological advancement, this shift represents a critical response to the challenges of food safety, waste reduction, and supply chain efficiency in an increasingly interconnected world. As consumer expectations for fresh, high-quality produce continue to rise alongside the expansion of e-commerce and direct-to-consumer models, IoT emerges as an indispensable tool for stakeholders across the industry, promising a future where precision and reliability are the norm.

Understanding IoT’s Transformative Role

Real-Time Monitoring and Quality Assurance

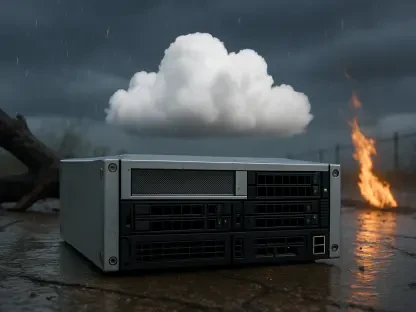

The cornerstone of IoT’s impact on agri-logistics lies in its ability to provide real-time monitoring of perishable goods, ensuring their safety and freshness throughout the supply chain. Advanced hardware such as sensors, GPS trackers, and RFID devices continuously capture critical data on temperature, humidity, and location during storage and transit. These tools feed into cloud-based platforms that allow stakeholders to access live updates and respond swiftly to any deviations that could compromise product quality. For products like meat and seafood, where even minor temperature fluctuations can lead to spoilage, this level of oversight is invaluable. By maintaining optimal conditions, IoT systems help prevent losses that have long plagued the industry, offering a lifeline to businesses aiming to deliver top-tier goods to discerning consumers.

Beyond immediate tracking, IoT solutions enhance quality assurance by enabling traceability across the supply chain, a factor increasingly demanded by both regulators and customers. Detailed records of environmental conditions and transit history allow for quick identification of issues if a product fails to meet standards. This transparency not only builds trust with end consumers but also ensures compliance with stringent food safety regulations that vary across regions. Retailers and food processors, in particular, benefit from this capability, as it allows them to guarantee the integrity of their offerings, even after long-distance transportation. The result is a more reliable food ecosystem where quality is no longer a gamble but a measurable, manageable outcome.

Automation and Precision in Supply Chains

Automation stands as a defining feature of IoT-driven cold chains, bringing unprecedented precision to the management of perishable goods. Through integrated software solutions, data collected from sensors triggers automated responses, such as adjusting cooling systems in storage units or rerouting shipments to avoid delays. This minimizes human error and ensures that conditions remain optimal without constant manual intervention. For instance, predictive maintenance software can anticipate equipment failures before they occur, preventing costly disruptions during the transport of delicate items like fruits and dairy. Such precision directly translates to reduced spoilage and waste, addressing one of the most pressing challenges in agri-logistics.

Moreover, the ability to make data-driven decisions through IoT systems elevates supply chain efficiency to new heights. Fleet management tools analyze transit conditions and optimize routes, cutting down on fuel costs and delivery times while maintaining product integrity. This is particularly crucial as global trade expands, requiring adherence to international standards for temperature control and traceability. Stakeholders across the board—from farmers to logistics providers—find that continuous tracking and automated alerts empower them to meet these standards with confidence. The shift toward smarter, more responsive supply chains marks a significant departure from traditional methods, positioning IoT as a vital component of modern agricultural logistics.

Market Dynamics and Adoption Trends

Key Drivers of Growth

The rapid expansion of IoT-based cold chain solutions in agri-logistics is propelled by several powerful drivers, with the escalating demand for efficient food supply chains at the forefront. As urbanization accelerates and global population growth places greater strain on food resources, the need to deliver fresh produce to densely populated areas becomes paramount. IoT technologies address this by enabling precise monitoring and management of perishable goods over long distances, ensuring they reach consumers in optimal condition. This capability is especially critical in meeting the expectations of modern markets where freshness is synonymous with quality, driving stakeholders to invest in smarter logistics solutions.

Another significant factor fueling growth is the surge in international trade, which necessitates compliance with diverse regulatory frameworks across borders. IoT systems provide the tools to document and maintain conditions during transit, facilitating adherence to these standards with ease. Additionally, the rise of e-commerce and direct-to-consumer delivery models has intensified the push for reliable cold chain infrastructure. Consumers now expect rapid access to high-quality perishables, and IoT offers the speed and accuracy needed to fulfill such demands. Together, these forces create a robust environment for market expansion, positioning IoT as a cornerstone of sustainable food distribution.

Challenges Hindering Adoption

Despite its transformative potential, the adoption of IoT in cold chain logistics faces notable obstacles, with high initial costs standing as a primary barrier. The investment required for hardware like sensors and trackers, alongside software and connectivity infrastructure, can be prohibitive, particularly for small and medium-sized enterprises in the agricultural sector. These upfront expenses often deter smaller farmers and logistics providers from embracing the technology, even though long-term benefits like waste reduction and efficiency gains are clear. Bridging this financial gap remains a critical challenge for achieving widespread implementation across the industry.

Equally concerning is the issue of inconsistent network coverage, especially in rural and remote areas where much of agricultural production occurs. Real-time monitoring, a key feature of IoT systems, relies heavily on stable connectivity to transmit data and trigger responses. Without reliable networks, the effectiveness of these solutions diminishes, leaving gaps in the supply chain where spoilage risks increase. Furthermore, data security and privacy concerns add another layer of hesitation, as stakeholders worry about the vulnerability of sensitive supply chain information on digital platforms. Addressing these connectivity and security hurdles is essential to unlocking the full potential of IoT in agri-logistics.

Stakeholder Perspectives and Applications

Diverse Benefits Across End-Users

IoT cold chain solutions deliver tailored advantages to various stakeholders, each leveraging the technology to address unique operational needs within the agri-logistics ecosystem. Farmers and growers, often at the start of the supply chain, utilize IoT to monitor storage conditions and minimize post-harvest losses, ensuring that crops like vegetables and fruits retain their value during initial transport. By receiving real-time alerts on temperature anomalies, they can take swift action to protect their produce, thereby securing better returns. This targeted application of IoT helps bridge the gap between rural production and urban markets, enhancing profitability for those at the source.

Retailers, on the other hand, prioritize IoT for maintaining product freshness on store shelves, a key factor in meeting consumer expectations for quality. Real-time data allows them to track inventory conditions and ensure that items like dairy and meat remain safe for purchase, reducing the risk of customer dissatisfaction. Food processors integrate IoT to streamline production and distribution, maintaining strict control over environmental factors during processing. Meanwhile, logistics providers harness these systems to optimize fleet management, ensuring timely deliveries under ideal conditions. This diversity in application underscores IoT’s versatility, catering to distinct yet interconnected roles within the supply chain.

Versatile Applications in Agri-Products

The scope of IoT cold chain solutions extends across a broad spectrum of agricultural products, each with specific storage and transport requirements that the technology adeptly addresses. For grains and cereals, IoT systems monitor humidity levels to prevent mold growth during long-term storage, preserving quality over extended periods. In contrast, perishable items like fruits and vegetables benefit from precise temperature control to slow ripening and extend shelf life during transit. This adaptability ensures that a wide range of produce reaches markets in peak condition, supporting both local and global food systems with reliable logistics.

For high-value products such as meat, seafood, and dairy, IoT offers even more critical interventions by maintaining stringent cold environments to prevent bacterial growth and spoilage. Sensors embedded in transport units provide continuous feedback, allowing for immediate adjustments if conditions deviate from the norm. Additionally, niche categories like flowers and plants, often overlooked in logistics discussions, gain from IoT through tailored monitoring that preserves their aesthetic and commercial value. Processed foods, with their own set of preservation needs, also see improved handling through data-driven insights. This wide applicability highlights IoT’s role as a universal solution in managing the complexities of diverse agricultural goods.

Regional Insights and Future Potential

North America’s Leadership and Europe’s Growth

Regionally, North America holds a commanding position in the IoT cold chain market as of 2024, driven by its advanced infrastructure and rigorous food safety regulations that encourage widespread adoption. Significant investments in intelligent tracking solutions, coupled with strong consumer demand for fresh, high-quality produce, have cemented the region’s dominance. Government initiatives further support this trend by promoting technologies that enhance supply chain transparency and compliance, making North America a benchmark for IoT integration in agri-logistics. This leadership reflects a mature market ready to set standards for others to follow.

Europe, however, is emerging as the region with the fastest projected growth over the forecast period through 2034, fueled by a concerted push to modernize agricultural supply chains. Efforts to reduce food waste, combined with the expansion of organized retail and export activities, drive the demand for efficient cold chain solutions. The region’s focus on accessing global markets necessitates cost-effective logistics, and IoT delivers the precision needed to compete internationally. As Europe invests in cutting-edge technologies and infrastructure, it sets a dynamic pace for growth, potentially reshaping the global landscape of agri-logistics in the coming years.

Technological Innovations on the Horizon

Looking ahead, the integration of artificial intelligence (AI) and machine learning (ML) into IoT cold chain systems promises to elevate their capabilities, addressing current limitations and sustaining market growth. AI-driven predictive analytics can forecast demand with greater accuracy, allowing stakeholders to adjust inventory and logistics proactively. This reduces overstocking and shortages, optimizing resource use across the supply chain. Such advancements are poised to tackle existing challenges like high costs by improving operational efficiency, making IoT solutions more accessible to a broader range of businesses in the agricultural sector.

Furthermore, ML algorithms enhance automated responses to supply chain disruptions, such as equipment failures or unexpected delays, by learning from past data to suggest optimal solutions in real time. This level of automation not only minimizes downtime but also strengthens resilience against unforeseen challenges. As these technologies converge with IoT, the market’s trajectory toward US$ 149.9 billion by 2034 appears increasingly achievable. The continuous evolution of digital tools signals a future where agri-logistics is not just reactive but anticipatory, setting a new standard for efficiency and sustainability in food distribution.