The continual advancement in construction technology marks a transformative era for the industry. The collaborative efforts between KDDI, KDDI Research, KDDI Smart Drone, and Shimizu Corporation, with a significant boost from Starlink’s “Satellite Mobile Link,” herald a groundbreaking milestone. These entities have successfully demonstrated real-time transmission of 3D point cloud data during the construction of the Hokkaido Shinkansen Oshima Tunnel. This leap in technology promises to redefine construction progress monitoring, drastically cutting inspection times and enhancing project management.

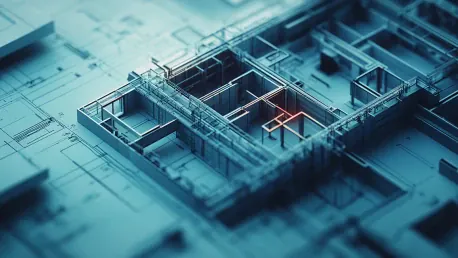

The Emergence of 3D Point Cloud Data in Construction

Overcoming Traditional Challenges

3D point cloud data has emerged as a vital tool for surveying construction sites due to its ability to provide in-depth, three-dimensional information. Nevertheless, the sheer volume of this data has traditionally posed significant challenges. Conventional methods often required physical transportation or lengthy uploads to cloud-based systems, demanding extensive labor and time. This limitation made routine inspections labor-intensive and sluggish.

The adoption of 3D point cloud data on construction sites has sparked considerable interest, primarily due to its ability to capture exact spatial measurements and detailed structures. Yet, its application has been hindered by the time necessary to process and transmit such a massive volume of data. Traditional methods of data transportation were often stricken with inefficiencies, whether through physical means or over unreliable digital networks. This bottleneck frequently resulted in delays, affecting the overall timeline and efficiency of construction projects. The necessity to address these inefficiencies became imperative as the construction industry sought more accurate and expeditious solutions to streamline operations.

Harnessing Collaborative Innovation

The project involving au communication network by KDDI, augmented by Starlink’s Satellite Mobile Link, tackled these limitations head-on. The integration of LiDAR 3D scanners on quadruped robots and drones enabled efficient data collection. The data was instantly transmitted to Shimizu Corporation’s innovation center, demonstrating the power of real-time technological interconnectivity.

Utilizing advanced real-time transmission capabilities, the project underscored the importance of collaborative innovation in overcoming traditional challenges. Each entity’s expertise and resources converged to create a seamless process—from data collection to real-time transmission. The integration of LiDAR 3D scanners on robots and drones ensured precise and quick data acquisition, while Starlink’s Satellite Mobile Link guaranteed consistent and rapid data transmission. This holistic approach enabled immediate data processing and usage, significantly reducing delays and human error. This collaboration not only exemplified the advantages of multi-entity cooperation but also set a precedent for future technological integrations in construction and beyond.

Technological Breakthroughs in Real-Time Data Transmission

The Role of Real-Time 3D Point Cloud Encoder

A pivotal element in this technological stride was the real-time 3D point cloud encoder developed by KDDI Research. This encoder, equipped on small onboard computers mounted on drones and robots, significantly reduced data size—trimming the required bandwidth to an impressive one-twentieth of the original size. The result was a dramatic reduction in transmission time from hours to under 10 seconds, thus enabling real-time data relay.

By effectively diminishing data size without compromising quality, the real-time 3D point cloud encoder revolutionized how construction data is handled and transmitted. The rapid compression and encoding processes facilitated a smoother, faster transfer of information, ensuring that construction management could rely on up-to-date data almost instantaneously. This innovation meant that the traditionally cumbersome process of data transmission, which could take several hours, was accomplished in mere seconds. This breakthrough has set a new benchmark for data transmission standards, bringing real-time capabilities to the forefront of construction technology and enabling faster decision-making and problem-solving on-site.

Enhancing Construction Efficiency

By implementing these innovations, the project notably improved efficiency in construction management and inspection processes. It allowed for swift, automated data transmission, supporting remote monitoring and control. Real-time 3D data capabilities reduce the need for frequent on-site presence, leading to simplified workflows and substantial time and cost savings.

The ability to remotely monitor and control various aspects of construction through real-time data not only streamlines operations but also enhances safety and productivity. Automating data transmission and reducing reliance on constant manual oversight minimizes human error and fosters a more efficient use of resources. The innovative technologies applied in this project offer an exemplary model for construction organizations aiming to modernize operations, ensuring that essential tasks such as inspections and quality control are carried out promptly and accurately. These advancements underscore a significant leap towards the digital transformation of construction management, paving the way for more sophisticated and integrated construction processes.

Future Prospects: Remote Construction Management

Towards Autonomous Operations

The successful application of these technologies paves the way for future innovations in remote construction management. The potential for remote control, semi-automation, and autonomous operations of drones and robots can revolutionize how large-scale construction projects are monitored and managed. This includes intricate tasks such as rebar inspections and concrete pouring, which are essential but traditionally cumbersome.

By embracing remote and autonomous operational capabilities, the construction industry can achieve unprecedented levels of efficiency and accuracy. The ability to perform critical tasks without on-site human intervention means projects can continue uninterrupted around the clock, minimizing delays and improving overall project timelines. Autonomous drones and robots equipped with advanced sensors and real-time data transmission can perform detailed inspections and intricate construction activities with precision, reducing the need for manual labor in high-risk environments. This transformative approach promises to redefine traditional construction methodologies, providing a safer, more efficient, and highly productive means of managing complex construction tasks.

Digital Twins and Large-Scale Data Handling

One of the prominent future applications of real-time 3D data transmission lies in the concept of digital twins. Digital twins facilitate the management of large-scale point cloud data, enabling a digital replica of physical assets for predictive analysis and real-time monitoring. This technology ensures higher precision and efficiency in managing construction projects of significant scale.

Digital twins play a crucial role in transforming the construction industry by allowing for the creation of highly accurate, virtual models of physical structures. These models can be continuously updated with real-time data, providing construction managers with a dynamic and interactive representation of the project. This capability enhances predictive maintenance, efficient resource utilization, and real-time troubleshooting, furnishing an invaluable tool for complex project management. The integration of digital twins with real-time 3D point cloud data ensures a seamless flow of accurate information, greatly enhancing the overall management and execution of construction projects. This powerful combination is set to become a cornerstone in the future landscape of construction technology.

Integration and Impact on the Construction Industry

Adoption of Cutting-Edge Solutions

The consortia’s efforts signify a broader trend of integrating advanced technologies to modernize traditional, labor-intensive construction sectors. By adopting cutting-edge solutions, companies can enhance operational efficiency, project management accuracy, and adherence to safety protocols.

The integration of innovative technologies in construction is paving the way for a more streamlined and robust industry. The ability to leverage real-time data, automation, and advanced analytical tools significantly enhances decision-making processes and ensures greater adherence to safety and quality standards. This modernization drive is characterized by the adoption of cutting-edge solutions that reduce human intervention in high-risk tasks, thereby promoting a safer working environment. The consortia’s groundbreaking achievements underscore an accelerated shift towards digital construction, where sophisticated technology is harnessed to optimize all aspects of construction management and execution.

Affirmations from Industry Leaders

The ongoing advancements in construction technology mark a transformative era in the industry. The synergistic efforts of KDDI, KDDI Research, KDDI Smart Drone, and Shimizu Corporation, bolstered by Starlink’s “Satellite Mobile Link,” signify a groundbreaking achievement. These organizations have successfully demonstrated the real-time transmission of 3D point cloud data during the construction of the Hokkaido Shinkansen Oshima Tunnel. This remarkable technological leap promises to revolutionize how construction progress is monitored, dramatically reducing inspection times and enhancing overall project management.

Real-time 3D point cloud data transmission enables immediate insight into construction progress, allowing for quicker detection of discrepancies or issues. This technology facilitates more efficient resource allocation and task prioritization, ensuring that projects stay on schedule and within budget. The integration of advanced communication tools and construction methodologies marks a new chapter in the industry’s evolution, offering a glimpse into a future where technology and construction seamlessly converge to create smarter, more efficient building processes.